3D Ice Printing Experimentation

The following videos are the first set of positive experiments in 3d ice printing using super-cooled purified water. These tests were completed after Mars Ice House was awarded NASA's 3D Printed Habitat Competition and done in collaboration with Petr Novikov. These experiments would ideally be performed in environments with temperatures below zero degrees Celsius, using the deposition of supercooled water onto ice particles. The system consists of one mobile robot capable of moving about the printed structure during the printing process, and an outside navigation system capturing the position of the robot and controlling it in real time.

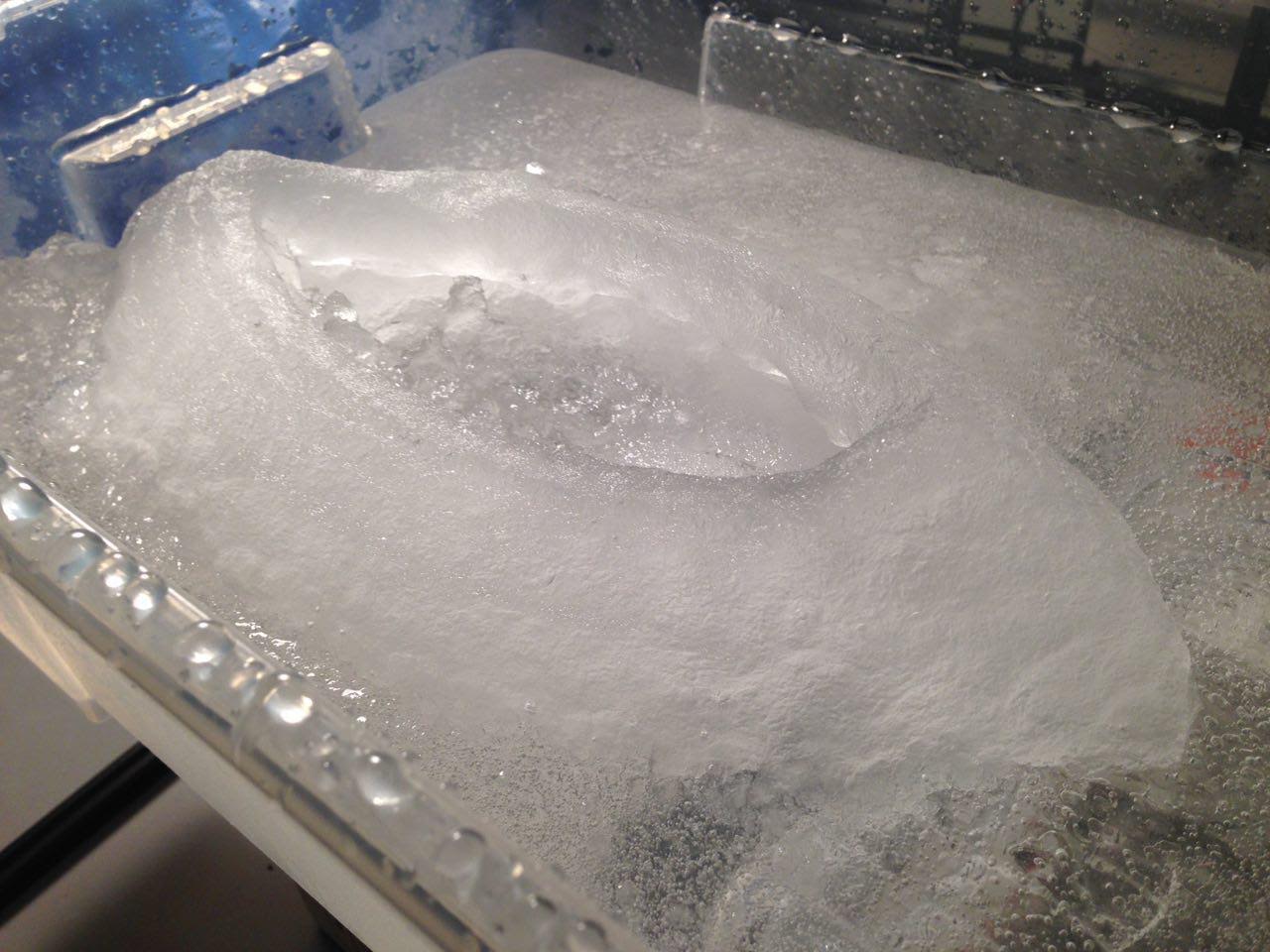

In these tests regular tap water was turned into purified supercooled water (from -1C to -18C), and deposited from an end effector. In order to move forward with this prototype we must first design the filtering/chilling system and then design the end effector and flow control. Currently the plan is to use a reverse osmosis filter and a refrigerant-to-water heat exchanger. However, in case these approaches fail, new approaches may be introduced. Since there is no known analog of supercooled water 3D printing, experiments have to be carried out to better understand the process, its limits and qualities of the resulting structures. In particular we would need to test the end effector on a CNC machine or robotic arm to find the best parameters for printing (flow speed, shape of the stream, movement speed, movement paths etc.)